Hygienic Stainless Machine Mount

The XH machine foot is certified according to the 3A hygienic standard: “88-00” and certified according to the EHEDG hygienic standard TYPE EL - CLASS 1. The patented XH machinefoot is sealing all moveable parts 100 % hygienically, even if the load on the foot is removed.

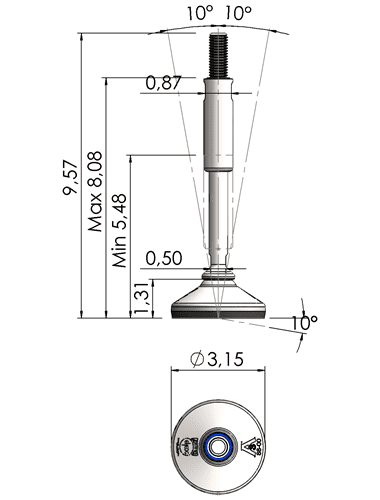

The design of the XH system reduces the cleaning effort to an absolute minimum. The sleeve covers the thread, and also functions as a nut. The machine foot admits slopes up to 10° of floors and equipment. The XH machine foot is marked with the 3A and EHEDG logo. Instructions of mounting/cleaning, the 3A and EHEDG certificate are sent together with the shipment. XH65, XH80, XH105, XH125, XH150

NGI fundamentally adheres to all applicable directives and standards. All information is based on the current state of knowledge and is subject to change. We attentively follow the revisions and amendments to these directives and will design our products accordingly. This ensures that products from NGI are always in compliance with currently valid requirements.

Our product category is not covered by the scope of application of the EC directive for machinery. For this reason, they cannot be furnished with the CE marking in accordance with the EC directive for machinery.

NGI A/S, Virkelyst 3-7, 9400 Nørresundby, Denmark, hereby declares that the design is according to 3-A, USDA & EHEDG guidelines and regulations specified in the following.

Furthermore, we declare that the listed materials applied in our products comply with the demands for materials used within the food and pharmaceutical industries.

Applications:

- Dairy

- Brewery

- Pharmaceutical Industry

- Applications with the highest demands for hygiene and cleaning

Materials, Surface Roughness, Fabrication and Geometry

Metallic surfaces are constructed from AISI 304 grade stainless steel and are corrosion resistant under the specified conditions of use including those of cleaning. The elastomeric components are constructed from FDA approved NBR and TPE Santoprene® rubber material. The sealing washers are constructed from Aramid fiber material. All materials used are considered nontoxic and are non-absorbent.

All exposed metallic surfaces are finished to maximum surface roughness values of 1.6 pm Ra. All elastomeric components and sealing washers are left as moulded with no hand trimming and all surfaces are considered smooth enough to ensure superior cleanability.

There are no exposed dissimilar metal-to-metal contact areas in the construction where galvanic corrosion could occur.

Hygienic seals permit access for easy cleaning with no inaccessible pockets or crevices.

There is no risk of exposed threads and no unsealed metal-to-metal joints in the finished construction.

All exposed surfaces have a smooth finish so that soil may be cleaned from the surface using manual cleaning techniques and be free of pits, folds, cracks, crevices, and other imperfections in the final fabricated form.

Drainability and Installation

The levelling feet are designed to be self-draining and contain no horizontal ledges. Comprehensive instructions are provided containing detailed information to ensure compliance with the 3-A, USDA & EHEDG design criteria.

The 3-A Sanitary Standard 88-00 requires that when leveling feet are properly mounted on the equipment, they shall provide a minimum clearance between the lowest part of the equipment and the floor of no less than 4.0 inches (102 mm) if the equipment outlines an area in which no point is more than 12.5 inches (318 mm) from its’ nearest edge. If the equipment outlines an area in which any point is more than 12.5 inches (318 mm) from its’ nearest edge the clearance shall be at least 6 inches (152 mm).

The EHEDG guideline recommends a minimum clearance between the equipment and the floor or wall of 300 mm for easy cleaning and inspection.

When fasteners are required only dome nuts must be used. The exposed interfaces shall be sealed with sealing washers and there must be no threads exposed in the installed configuration of the levelling feet.